Key Takeaways

The lifespan of a wire rope is maximized through a consistent maintenance program focused on three key areas: proper lubrication, regular inspection for wear, and correct handling/storage. Lubrication reduces internal friction and prevents corrosion, while rigorous inspections identify signs of degradation like broken wires or crushing before they lead to failure. Proper handling ensures the rope is not damaged during use or storage.

Core Answer

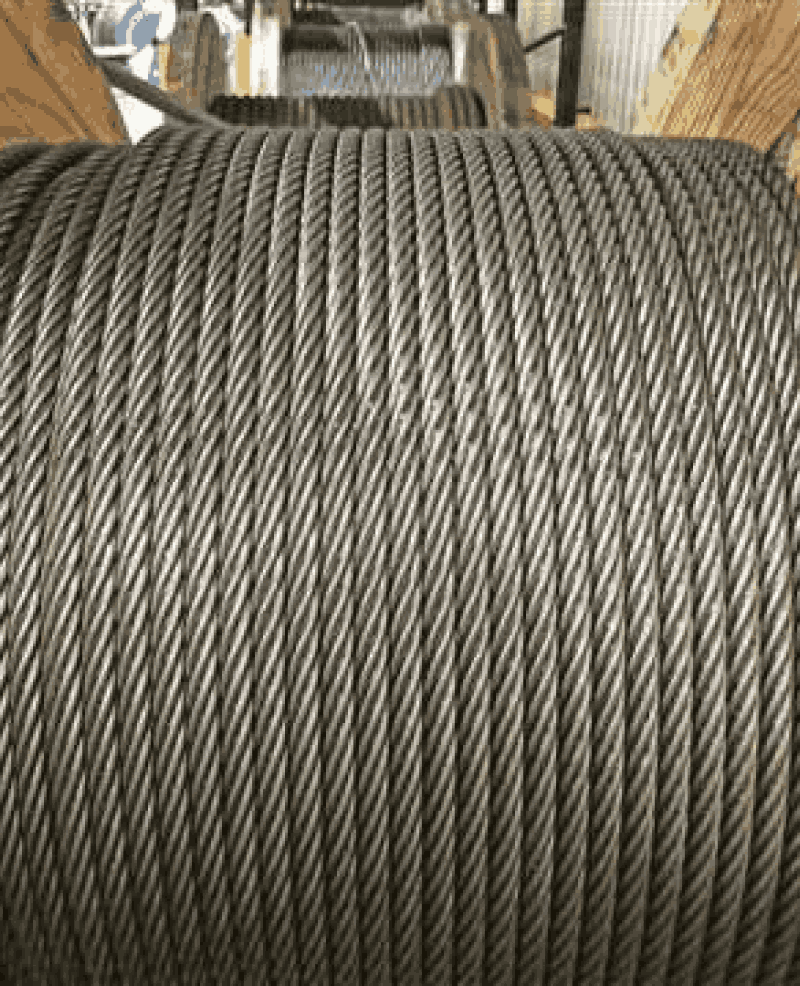

To extend the functional life of a wire rope, you must treat it as a critical piece of machinery. The single most important maintenance step is applying the correct type of lubricant, which penetrates the core of the rope to protect internal wires from friction and rust. This should be combined with a frequent visual inspection schedule to check for common signs of wear, such as broken wires, diameter reduction (“necking”), corrosion, and structural damage. Finally, ensuring the rope spools correctly onto its drum and is stored in a clean, dry environment will prevent premature damage.

Step 1: The Right Lubrication Process

Lubrication is not just a surface treatment; it is vital for the rope’s internal health.

- Frequency: Lubrication frequency depends on the operating environment. Ropes in corrosive or dusty environments may need lubrication monthly, while those in cleaner settings may go longer.

- Cleaning: Before applying new lubricant, clean the rope with a wire brush or compressed air to remove old grease, dirt, and debris. This allows the new lubricant to penetrate the core.

- Application: Apply a penetrating lubricant using a drip, spray, or pressure applicator system. The goal is to get the lubricant into the core of the rope.

- Choosing a Lubricant: Use a lubricant specifically designed for wire ropes that will not only coat the surface but also flow into the internal strands.

Step 2: A Guide to Rigorous Inspection

Your inspection schedule should be consistent and thorough.

- Broken Wires: Note the number and location of broken wires. Consult industry standards for the maximum allowable number of broken wires before the rope must be retired.

- Diameter Reduction: Use a caliper to measure the rope’s diameter. A noticeable reduction in diameter (necking) is a sign of internal core failure.

- Corrosion & Pitting: Look for rust or signs of pitting on the wire surfaces. Internal corrosion is particularly dangerous as it is often invisible.

- Kinking or Crushing: Any area where the rope has been kinked, crushed, or bird-caged indicates severe damage, and the rope should be removed from service.

Step 3: When to Retire a Wire Rope

A wire rope must be retired when inspections reveal any of the following conditions, as specified by standards from bodies like the International Organization for Standardization (ISO):

- Excessive number of broken wires in a given length.

- Significant reduction in rope diameter.

- Severe corrosion or heat damage.

- Evidence of kinking, crushing, or core protrusion.

Follow-Up Questions

- Can you repair a damaged wire rope?

Generally, no. A wire rope that shows signs of significant wear or damage should never be repaired. It must be completely replaced to ensure safety. - What is the best way to store wire ropes?

Store them in a well-ventilated, dry, and covered area away from chemicals, moisture, and direct sunlight. Keep them on a rack or reel to avoid contact with the ground.

From supplying high-quality wire ropes to providing expert advice on maintenance, Partrid Investments is your trusted partner for lifting solutions in Zimbabwe. Get in touch to learn more.